MS500 Wood Floor Adhesive from New Era is a high strength, single-part silane polymer adhesive. The advantages of MS500 is that it can be used for bonding most types of wood fooring – including wood blocks, engineered, laminated & solid wood plank fooring and the New Era Range of Acoustic Underlays.MS500 is also compatible with underfoor heating systems. It cannot be used over bitumen based subfoors.

This adhesive is compatible over most substrates including sand and cement screeds, concrete, Anhydrite (Calcium Sulphate) screeds, stone and timber. For compatibility confrmation with the underfoor heating systems contained within the substrate contact the Technical Team.

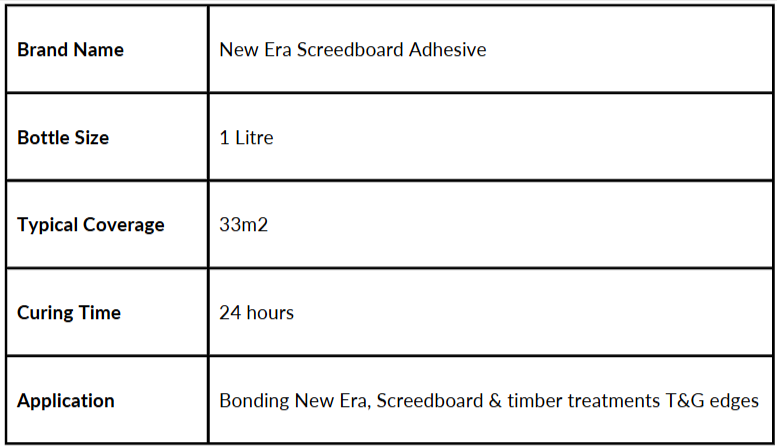

New Era Quiet Plank Adhesive is used to bond together Quiet Plank boards at the tongue and groove.

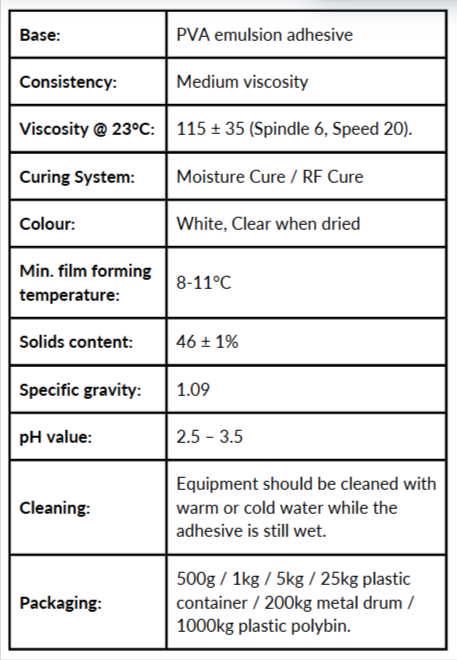

Hardwood Flooring Adhesive is a one-part PVA emulsion adhesive, specially formulated for wood bonding where a fast set, high bond strengths and excellent water resistance is required. The adhesive bonds virtually all woods, wood veneers, and mouldings and high-pressure decorative laminates (i.e. Formica). It is also suitable for use with a radio frequency press.

12 months in unopened packaging in a cool and dry storage place at temperatures between +5°C and +30°C.

PROTECT FROM FROST.

No danger labelling required.

The adhesive, substrate and ambient temperature should ideally be a minimum of 20°C. The moisture content of the wood materials should be uniform and should not exceed 12%.

Hardwood Flooring Adhesive can be applied by serrated glue spreader, roller or brush. Application is normally to one surface only at a rate of 150g/m2

Maximum 15 minutes depending on the materials to be bonded. Assembly times are dependant on ambient conditions and substrates used.

Pressure must be applied whilst the adhesive is still wet and should be a minimum of 30psi (2kg/cm2) depending on type of wood and structure.

Press times required depend on adhesive coating and substrates. Typical figures are:

Hot press:

Cold press:

Decorative laminate / plywood

Decorative laminate / plywood

70°C / 3-5 minutes

20°C / 15-20 minutes

Shelflife:

Road:

Maritime:

Air:

UN Number:

ADR

IMDG

ICAO/IATA-DGR

None

Free

Free

Free

Does not apply

Data contained in this document is for information only and is believed to be reliable. Trade Grade Products Ltd (TGP) cannot assume responsibility for results obtained by others over whose methods we have no control. It is the user’s responsibility to determine suitability of the product for any specific purpose and TGP is pleased to provide a sample upon request.

Before using this product ensure that you have been supplied with and have read carefully the following information.

Product Description

Flexible polyethylene flanking strip to isolate acoustic treatment from wall structures, reducing flanking sound.

Composition: Non-cross-linked, closed cell polyethylene

Application: Eliminate perimeter flanking transmission

Strip dimensions: FS30: 6mm x 30mm x 30mm x 2m

Simply request a callback and one of our friendly flooring experts will be in touch as soon as possible

Copyright © New Era 2024 | All Rights Reserved.

Designed & Developed by Prowling Tiger Media